Shaft generator retrofit difficult, not impossible says The Switch

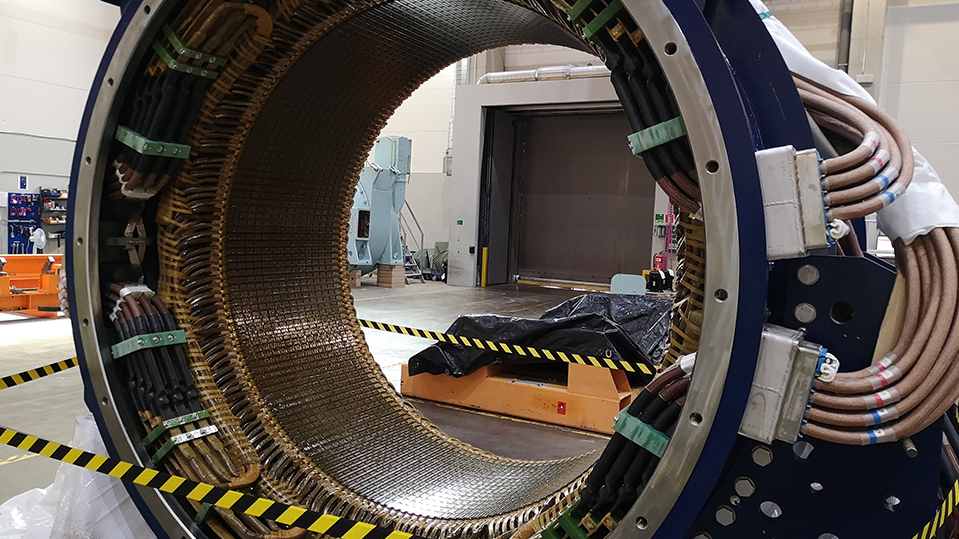

The workings of a shaft generator (Source: Charlie Bartlett)

Because it can use the vessel’s most efficient engine – a gearless, long stroke piston engine – to generate power, a shaft generator is regarded as substantially more efficient than firing up an auxiliary genset. This makes it possible to increase power generation efficiency by 10-20%. Permanent magnet (PM) technology, used in The Switch shaft generators, is able to achieve greater efficiency gains still of 4%, thanks to a lack of powered coils.

“These are big structures, and the main barrier to retrofit is that they require a big hole to be cut in the ship’s hull,” explained The Switch’s CEO Miika Reinikka.

Shaft generators cannot be assembled on site, as they require climate-controlled lab conditions to build, meaning that they must be transported and installed as one unit. However, the industry is currently considering similarly drastic retrofit projects including fitting of new fuel tanks and fuel supply systems for fuel switching. Retrofit, then, is a challenge, but not insurmountable. “It can be done, Reinikka agreed.