Egypt breaks ground with locally made underwater welding electrode

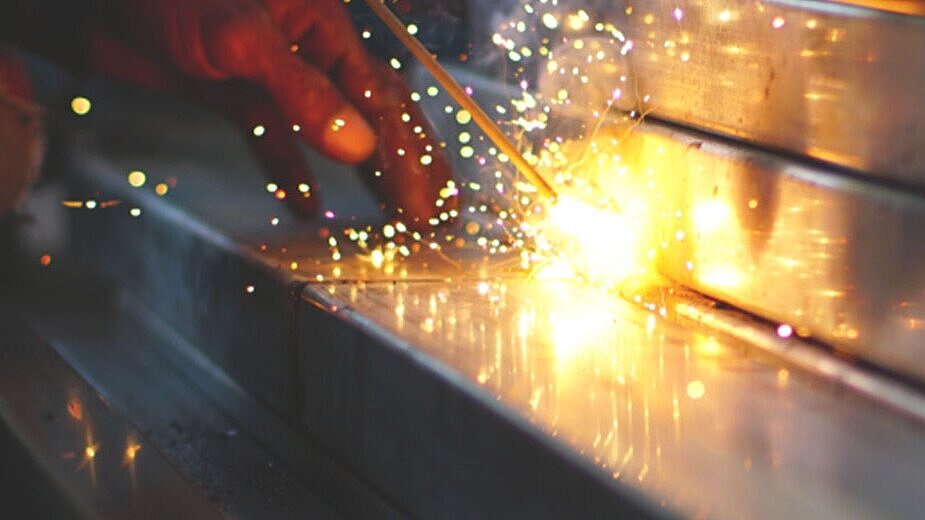

Underwater welding capability can remove the need for dry docking in some cases (Source: El Kadesia)

El Kadesia Engineering Industries has unveiled Egypt’s first domestically produced rutile-covered underwater welding electrode, capable of reliable use at depths of up to 20m in both fresh and saltwater environments.

This waterproof electrode addresses long-standing industry challenges: slow vessel repairs requiring dry dock lifts, costly import delays, and inconsistent weld quality underwater. El Kadesia’s product ensures hydrogen-free welds, strong penetration, and a high deposition rate, all while allowing easy re-strikes and slag removal.

The tool significantly benefits repair yards in the Eastern Mediterranean and Red Sea regions by offering a locally manufactured system for subsea welding, improving regional self-reliance and reducing procurement delays. Operationally, on site wet welding cuts downtime, eliminates towing costs, and reduces carbon emissions by avoiding unnecessary dry dock movements.

This breakthrough places Cairo among a select few global producers of underwater welding consumables and could be a springboard for even deeper operations. El Kadesia’s next goal is to extend the electrode’s working depth and integrate it with robotic welding crawlers, paving the way for unmanned subsea hull repairs.

A milestone for Egypt’s shipyards, the development could transform the efficiency and sustainability of ship repair in the region.